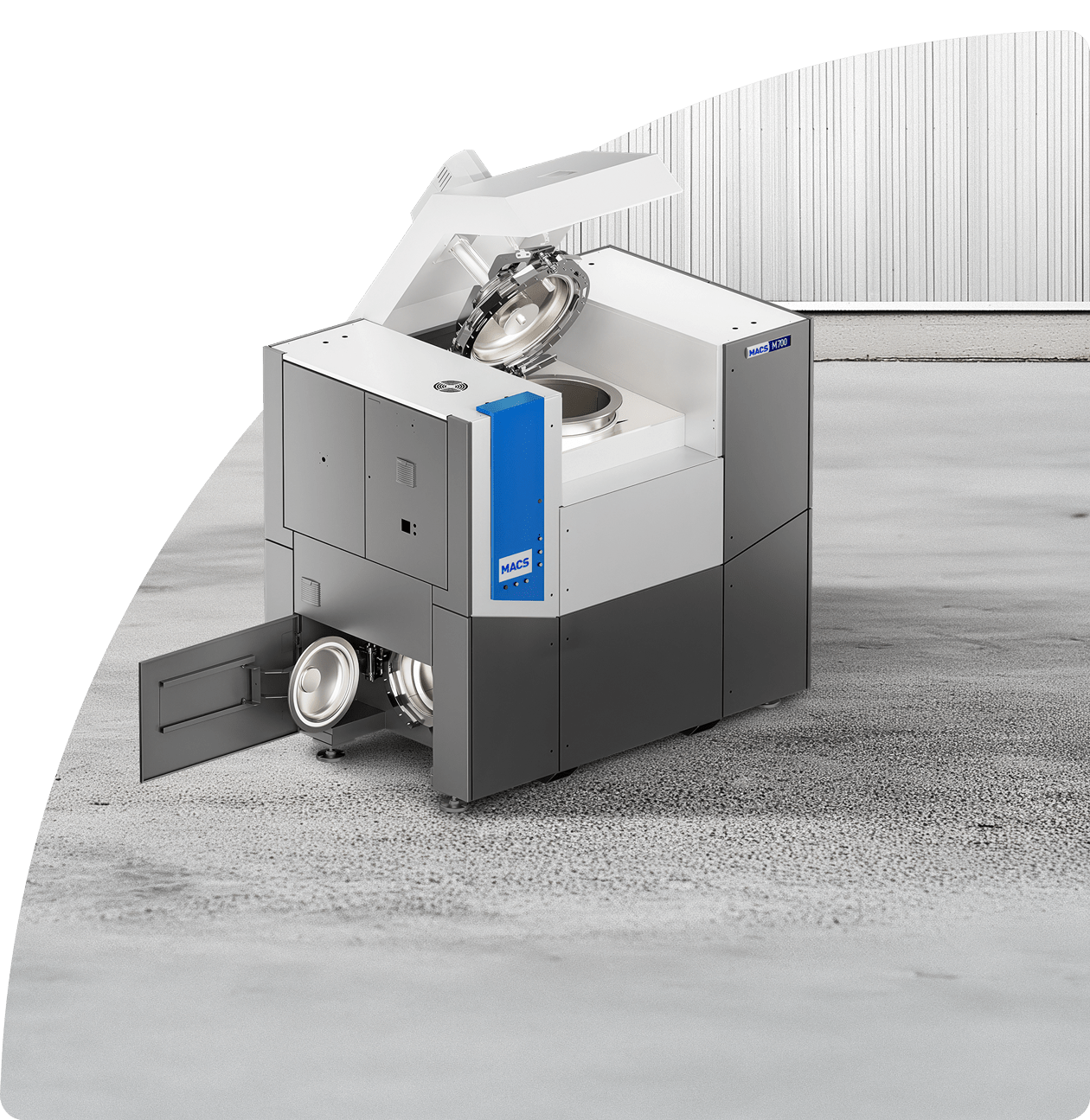

Dispose of toxic and medical waste in a sterile manner with Medi Steam

With the Medi Steam Compact series, you can dispose of hazardous medical waste safely, efficiently and cost-effectively. Find out how you can reduce waste volumes and treat them in an environmentally friendly way.

Setting new standards in medical waste processing

Using state-of-the-art autoclaving processes, heavily contaminated medical waste is shredded, sterilised and converted into harmless residual waste.

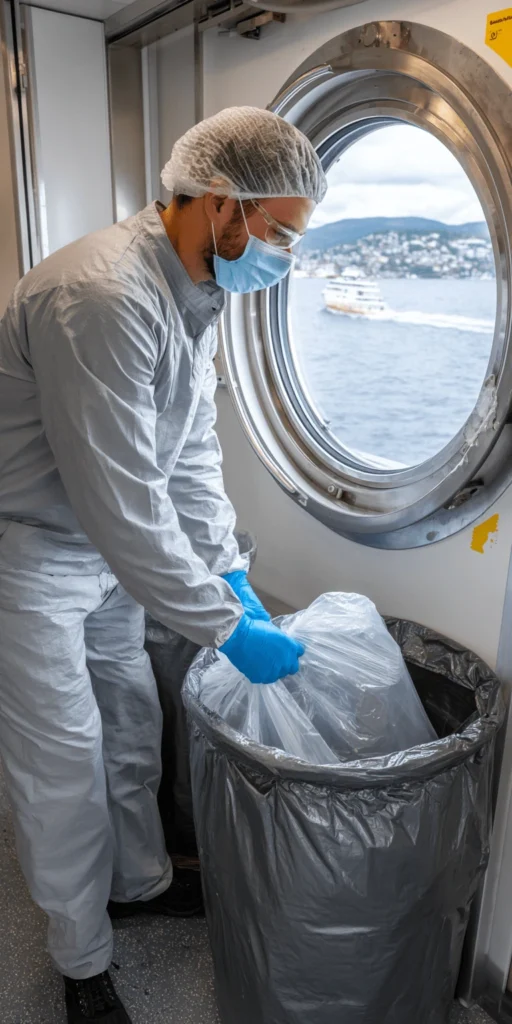

Decentralised

With the compact series, waste is treated directly at the point of origin, saving space and significantly reducing storage costs.

Certified

The RKI-certified process significantly exceeds WHO standards and achieves sterilisation reliability of SAL = 10-24 in just 10 minutes.

Safe

Plug-and-play installation, intuitive control and automatic operation at the highest level of sterility – supported by continuous software updates.

Materials and waste classes for processing

- Infectious waste

- Sharp-edged waste

- Pathological waste

- Pharmaceutical waste

- Kitchen waste

*Hazardous waste

Cytotoxic and radioactive waste excluded

Cost savings through reduction of waste volume

Medi Steam revolutionises waste treatment and reduces volume by up to 80%. For liquid waste, reductions of up to 97% are even possible.

10-24

Within 10 minutes, Medi Steam achieves a sterility assurance level (SAL) of SAL=10-24.

10-48

Within 20 minutes, Medi Steam achieves a Sterility Assurance Level (SAL) well above WHO standards of SAL=10-48.

750kg

MediSteam can handle up to 750 kg of infectious waste per cycle, revolutionising waste management.

How the macroeconomic cycle works

The environmentally friendly technology combines mechanical and thermal sterilisation in a pressure-regulated process – free of harmful substances and safe to use.

Let our success stories convince you

Start your sustainable future

From the initial consultation to financing, we accompany you to sustainable, profitable waste management.